Titanium chamber

Vacuum chamber technology with titanium alloy

By using titanium alloy as a material for vacuum chambers and vacuum parts, we have developed a technology that enables a vacuum system with extremely low outgassing. This makes it possible to obtain ultra-high vacuum / ultra-high vacuum quickly and easily.

This technology is the result of many years of research and development by a group including related companies centered on Yamaguchi University, and titanium alloy material, surface treatment, welding and brazing technology, other manufacturing technology, optimum design technology, etc. Taking advantage of its excellent characteristics, it opens the way for the application of vacuum that breaks the conventional wisdom. (Won the Exibitor Award at the US AVS Exhibition in November 2006)

Advantages of Titanium and Titanium Alloy Vacuum Chambers, Vacuum Parts

Titanium is originally a material suitable for application to vacuum. It has many advantages such as light weight, completely non-magnetic, low thermal expansion rate, low heat capacity, etc. Our technology has added to this inherently superior titanium material additional properties that are important for vacuum applications.

1. The development of surface treatment technology has made it possible to reduce outgassing by two to three orders of magnitude compared to stainless steel. This makes it possible to exhaust to an ultra-high vacuum at extremely high speed.

2. 2. The development of a special titanium alloy has made it possible to create a CF flange that is indispensable for ultra-high vacuum because it has higher strength and hardness than stainless steel.

3. The development of manufacturing technology has made it possible to reliably weld and braze titanium, which was difficult in the past. This has made it possible to manufacture vacuum chambers and vacuum parts with various complex shapes.

Products

We supply CF flanges, fittings and custom design vacuum chambers

- Flanges

- Fittings

- Vacuum chambers

- Custom components

- Titanium based vacuum systems

Features of our Titanium products

[ Ultra low outgassing rate ]

Our Titanium chamber has an extremely low outgassing rate which is 1/100 - 1/1000 of stainless steel chambers

After 1year shut off, the pressure built up only 10-7E Torr

[ Fast pumping to UHV ]

https://www.vista-UHV creation is easy. This example data for about 10L chamber pumped by 300L/sec TMP.

10-10E Torr of UHV was obtained within only 10 hours. Only 150 degree C and 6 hours baking is enough.

[ Light Weight ]

Density of Titanium is about 1/2 of stainless steel. It drastically reduces the weight of vacuum systems.

[ Strong ]

Our Titanium alloy is 70% stronger than stainless steel. Thickness of CF flange can be reduced by 30%.(and less than 1/2 weight)

The light and strong quality is suitable for transfer rods.

[ Hard ]

The hardness of the alloy is higher than stainless steel. It enables to form a nife edge of the Conflat flange, which is impossible by pure Titanium.

[ Low thermal expansion coefficient ]

Thermal expansion coefficient is 1/2 of Stainless steel and 1/3 of Aluminum. It is suitable for delicate mechanical parts used in vacuum.

[ Small heat capacity ]

As the heat capacity per volume is nearly a half of the stainless steel, quick heating/ cooling is possible. It shortens the time for baking and saves the energy.

[Non magnetic ]

Completely non magnetic characteristics are suitable for analytical instruments and applications in high magnetic field.

Characteristic Comparison

| Titanium Alloy | Pure Titanium | Stainless Steel (ANSI304) | Aluminum (A5052) | |

|---|---|---|---|---|

| Density (103kgm3) | 4.5 | < | 7.9 | 2.7 |

| Hardness (Hv) | 230-280 | 150 | 190 | 60 |

| Expansion Coefficient (10-6K-1) | 8.4 | < | 17 | 24 |

| Thermal Conductivity (Wm-1K-1) | 17 | < | 16 | 137 |

| Heat Capacity Per unit volume (10JKm-3) | 2.1 | < | 3.8 | 2.5 |

| Tensile Strength (MPa) | 650 | 340 | 516 | 175 |

| Young's Modulus (GPa) | 105 | 106 | 200 | 70 |

| Magnetism | No | No | Little | No |

Product Example

Titanium Flange

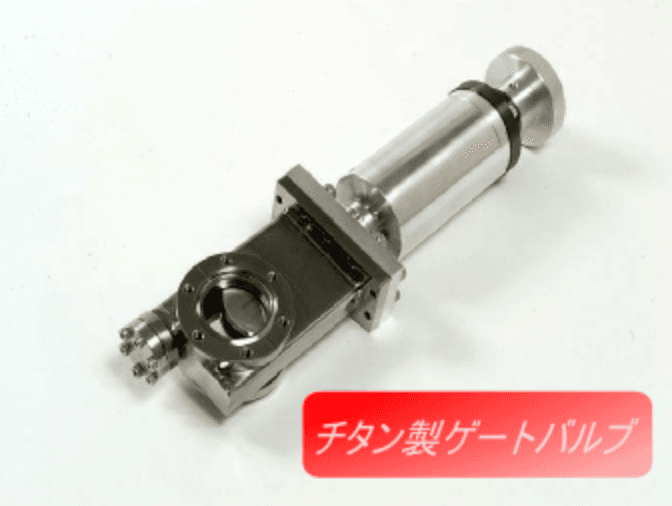

Titanium Gate Valve